Heat exchangers

- Home

- /

- Heat exchangers

Heat exchangers

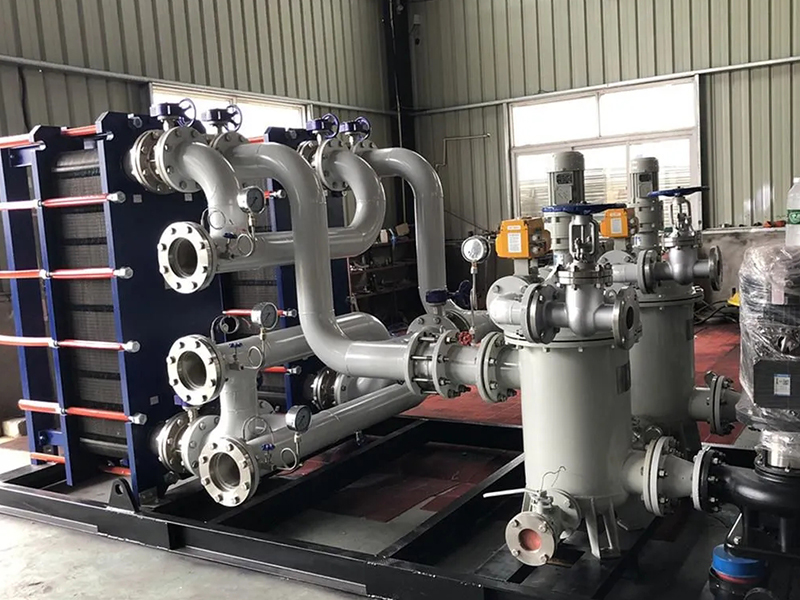

Our heat exchangers feature enhanced heat transfer design and corrosion-resistant materials to maximize energy efficiency and ensure stable operation. The compact structure adapts to diverse scenarios, while customized solutions precisely meet process requirements, providing reliable energy-saving and consumption-reduction support for your systems.

Get a quote now for your personalized plan

As a long-standing manufacturer of critical chemical production equipment, we specialize in addressing heat exchange challenges for factories, including cooling, heating, and waste heat recovery.

We can manufacture heat exchangers in various configurations, with material selection tailored to the characteristics of the processed materials, such as stainless steel or titanium, which exhibit high pressure resistance and corrosion resistance. The equipment can withstand pressures up to approximately 350 kg and operates within a temperature range from nearly-200°C to +550°C.

We will optimize the design through computer simulation and other methods to ensure efficient heat exchange and compact footprint. The equipment size and internal structure can be customized according to your requirements, and additional features such as automatic cleaning, anti-clogging, and leakage alerts can be integrated to help you save energy and reduce maintenance costs.

With extensive experience in manufacturing pressure vessels, we strictly control material selection and employ reliable welding and inspection technologies to ensure long-term stable operation under harsh conditions. All products are designed and manufactured in compliance with domestic and international standards.

If you require temperature control or heat recovery solutions, feel free to reach out to us. We will develop a customized plan tailored to your materials, thermal needs, and site conditions, with full technical support throughout the process.

Heat exchanger parameter specification table

Parameter Category | Parameter Item | Specification Value (Example) | Remarks |

Basic Information | Equipment Model/Type | Type F Shell-and-Tube/Plate Heat Exchanger | Including manufacturer’s model |

Nominal Heat Transfer Area | 50/100/200 | ㎡, design calculated value | |

Design Pressure/Temperature | 1.6/200; 2.5/300 | MPa/℃, common for shell side/tube side | |

Process Parameters | Shell Side Medium/Flow Rate | Heat Transfer Oil/50; Process Water/100 | m³/h |

Tube Side Medium/Flow Rate | Feed Gas/80; Cooling Water/150 | m³/h | |

Inlet/Outlet Temperature (Shell/Tube) | 200/120; 30/80 | ℃, Inlet/Outlet | |

Structural Parameters | Shell Diameter/Number of Tube Passes | 800/2; 1000/4 | mm/Pass |

Heat Exchange Tube Specification/Quantity | Φ25×2.5×1200/192; Φ19×2×1500/320 | mm/Unit, Outer Diameter×Wall Thickness×Length | |

Material & Safety | Main Material | Q235B; 304 Stainless Steel | Consistent for shell side/tube side |

Sealing Material/Protection Level | Fluororubber; IP54 | Suitable for working condition temperature | |

Performance & Certification | Executive Standard | GB151-2014 | Pressure Vessel Standard |

Warranty Period | 1-3 | Years, including core components |