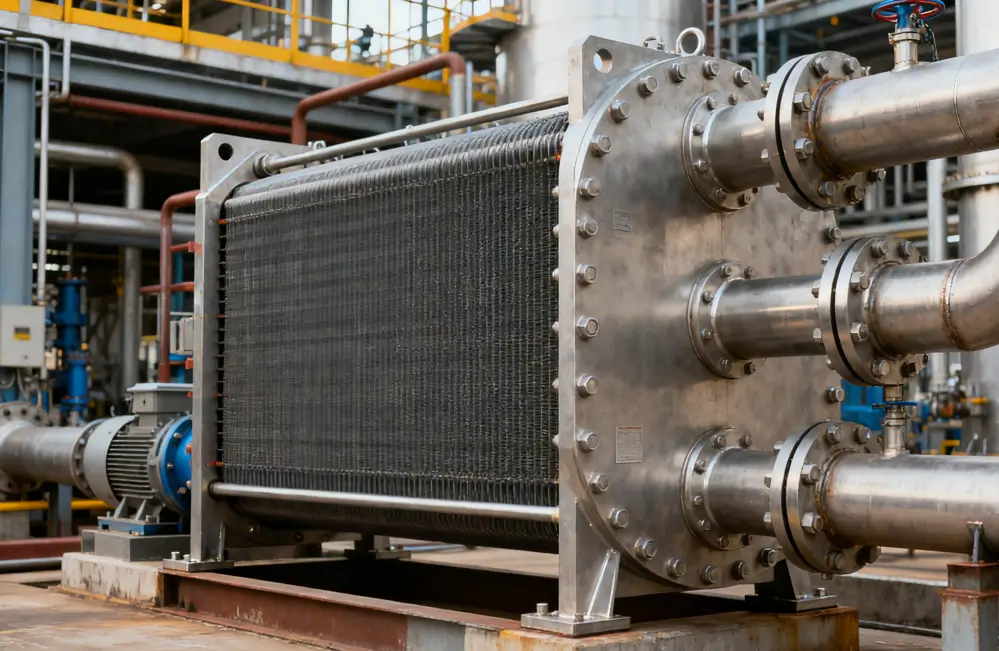

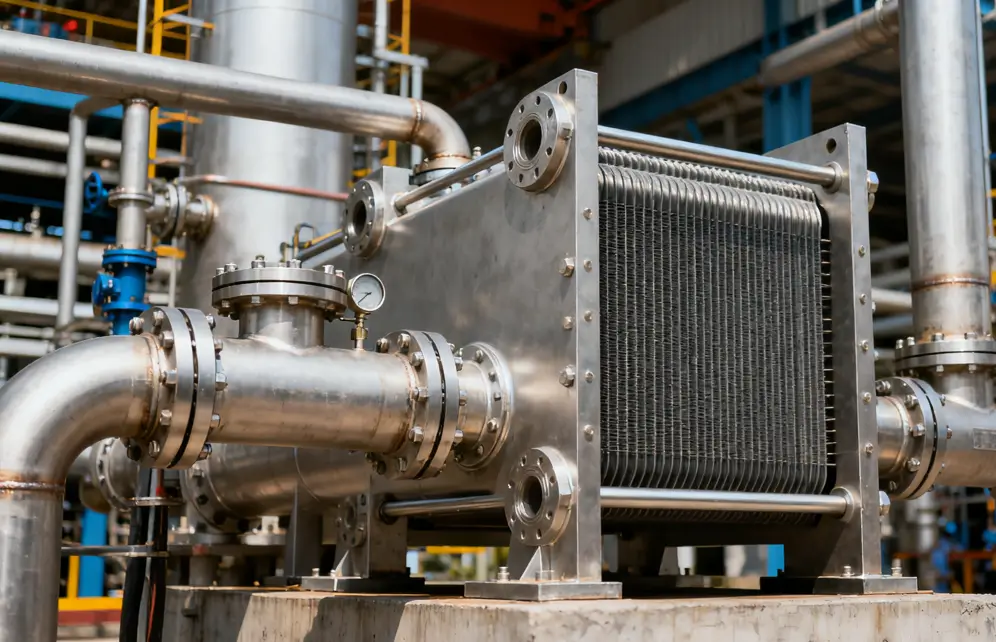

The scientific selection of heat exchanger materials has never been about “the more expensive, the better,” but rather “precise adaptation”—matching working condition requirements with strict standards, balancing safety, efficiency, and cost, so that every heat exchanger can “fulfill its maximum potential.”

The material of a heat exchanger is its first line of defense against harsh working conditions such as corrosion, high temperatures, and high pressures. The material must possess temperature resistance, corrosion resistance, weldability, and formability. In some special occasions, there are also requirements for the electrical conductivity and thermal conductivity of the material. Additionally, materials with high cost-effectiveness should be prioritized. Moreover, in the food and pharmaceutical industries, materials must comply with hygiene standards.

The material selection for heat exchangers is a multi-dimensional comprehensive decision-making process, which must involve professionals from multiple fields such as process, materials, and equipment. This ensures that the selected materials can provide long-term and reliable “armor” protection for the heat exchangers under specific working conditions.